FabLab Nepal in collaboration with Dassault Foundation and Ten to the Ninth Plus Foundation completed a 6-week digital fabrication and design workshop for youth groups: aptly named “Skill Enhancement in Design And Fabrication in FabLab Nepal” this July! Digital fabrication is a design and manufacturing workflow where digital data directly drives manufacturing equipment to form various part geometries. This data often comes from CAD (computer-aided design software), which is then transferred to CAM (computer-aided manufacturing) software. (“Digital Fabrication 101”). The out of this CAM is fed into machines such as 3D printers, CNC milling machines, Laser Cutters, and various other digital fabrication machines.

Even though the state of digital fabrication in developed countries has progressed in leaps and bounds, it is still in a nascent stage in Nepal. The concept of 3D printing and CNC milling has just started to enter the mindset of Nepali people. Hence, with the help of this workshop, FabLab Nepal aspires to accelerate the progress of digital fabrication among the populace ranging from high school students to eager professionals within Nepal.

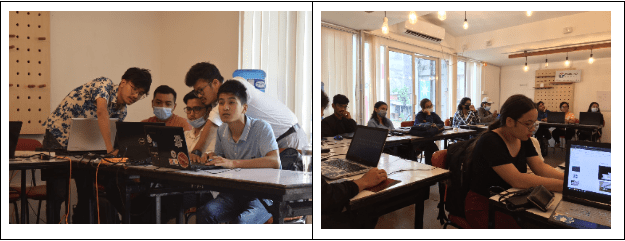

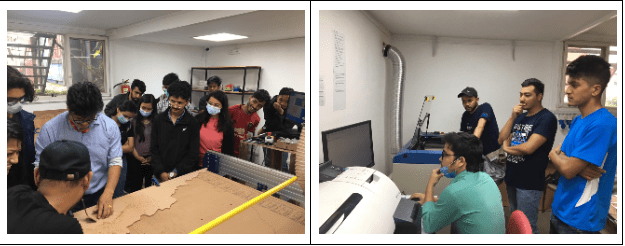

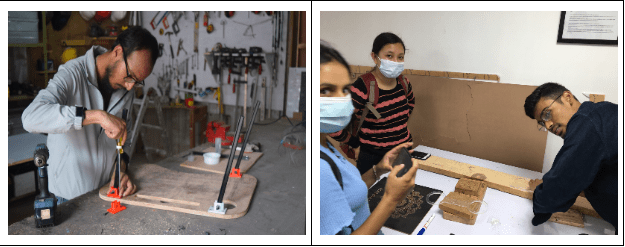

The first session of this workshop was carried out from June to the mid of July. We had two cohorts which included participants from a diverse backgrounds under same roof: engineers, high school students, professionals, animators and IT professionals. The workshop started with the basics of 2D and 3D design to set a foundation for the upcoming weeks which included classes in 3D Printing, Laser Cutter and CNC Router. Each class was 3 hours long, where students actively participated in discussions about the technology. After completion of a topic, the participants were given time in the following weeks to further hone their skills by performing hands-on training on each machine.

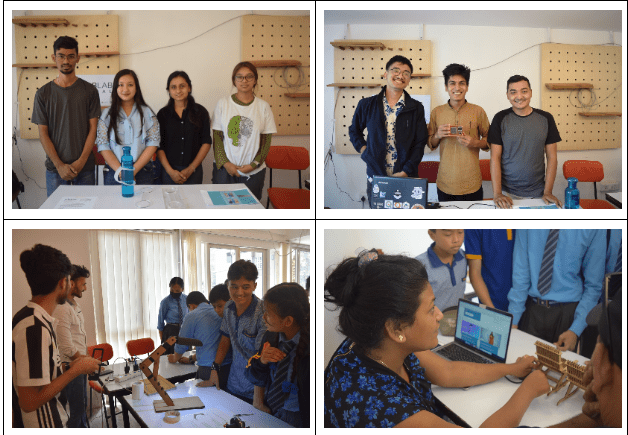

Throughout the workshop participants worked in groups of 4-5 members on their projects under the guidance of the Fablab Team. After an arduous 6-week-long journey, the participants’ ideas came to fruition, where their brilliant ideas are now enabled into tangible outcomes! We hosted a day-long exhibition at FabLab as a conclusion to the workshop where the makers showcased their creative outcomes and presented to the visitors. There was an assortment of projects which ranged from Silicon Bottle Holder for people with disability to Vector Thrust Mechanism for educational purposes. With positive feedback from the participants, we at FabLab Nepal are excited to be launching a new session in August. So keep an eye out for the call for application!

Testimonial

I signed up for this 6 weeks workshop, primarily, to be familiar with the processes involved in digital fabrication. Throughout the workshop, I learned a lot about the use of CAD software (Solidworks) and 3D Printer along with some knowledge about the workings of CNC, Laser cutting. In addition to developing new skills in the digital fabrication field, a supportive environment and camaraderie maintained by the Fablab team are what I admire the most. Overall, the experience was wonderful.

Sandip Adhikari (3rd Year Student, Aerospace Engineering, Pulchowk Campus IOE)