At Impact Hub Kathmandu, we’ve been focusing specifically on safety and safety training over the past few months. The initiative, spearheaded by FabLab Nepal, aims to enhance safe engineering practices across Nepal by providing comprehensive training to engineering students, designers, professional technicians, and business students. To improve engineering capabilities and promote safe practices in high-tech manufacturing, entrepreneurship, and design, Nepal’s first FabLab has embarked on a transformative project aimed at improving safe engineering practices across Nepal. We started this with safety training for our team, in-house.

Through our project, “Building Safe Engineering Designs and Practices for Nepal,” FabLab Nepal aims to equip engineering students, designers, professional technicians, and business students with essential safety training. With the support of the Royal Academy of Engineering, this initiative seeks to foster local skills, reduce accidents, and promote safe engineering practices throughout the country.

Significant milestones have been achieved since the project’s inception in August 2022. Firstly, a survey was conducted to assess the manufacturing industry’s existing design and safety practices. The data collected from the survey helped identify key problems and gaps that need to be addressed.

Building on this foundation, Fablab Nepal engaged with industry experts to collaborate and find solutions to the identified problems. Through extensive consultation and mapping exercises, the project ensured a holistic approach to providing safety training to Fablab staff members and developing a curriculum for safe engineering practices.

Furthermore, a crucial step towards ensuring a secure learning experience involved conducting a safety audit within FabLab Nepal’s workspace and office premises. The audit was conducted by a team of professionals from the Nepal Occupational Safety and Health Academy (NOSHA) and revealed areas where safety practices could be improved. Addressing the findings, FabLab Nepal implemented necessary changes, including providing proper personal protective equipment (PPE) and offering additional training on safe machine operation.

“We take the safety of our employees and participants seriously. The safety audit played a critical role in identifying potential hazards and enhancing our safety measures,” emphasized Mr Pallab Shrestha, Technical Lead of Fablab Nepal. “By creating a secure environment, we can provide effective training and minimize the risk of accidents.”

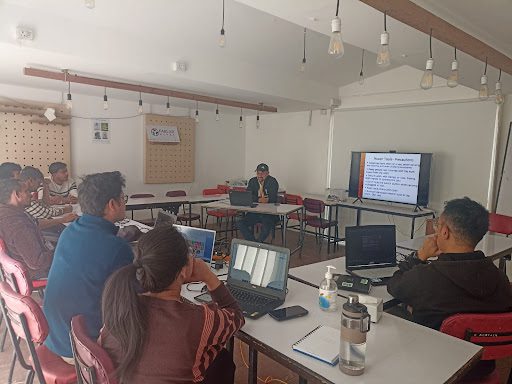

To ensure the highest safety standards, FabLab Nepal collaborated with safety experts from Nepal to train their staff members on the latest safety practices and designs for the use of CNC machines, laser machines, woodworking tools, electrical equipment, and electronics. After equipping their staff with the necessary expertise, FabLab Nepal developed comprehensive training courses and modules on safe engineering practices. The training courses were promoted to university students, makers, and designers interested in enhancing their safety skills and practices.

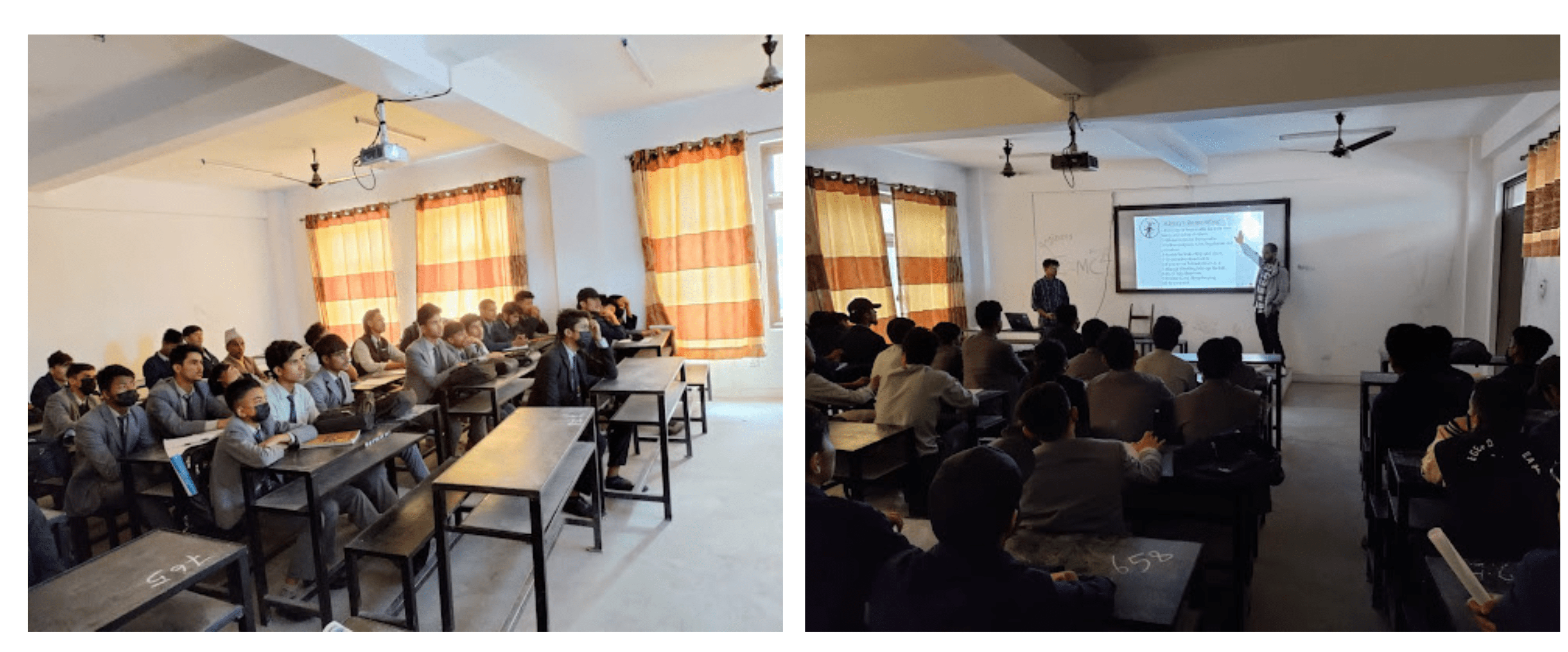

The project has delivered machine-specific safety training to 58 participants, including individuals from the Ministry of Industry, Balaju Institute of Science and Technology, and Padmodaya School. The participants come from diverse backgrounds, including undergraduate mechanical students, pre-diploma mechanical students, mechatronics students, and professionals. The feedback received from industry experts and employees has been overwhelmingly positive. Many have expressed their confidence in the training’s effectiveness in improving design and safety practices in Nepal. This validation further emphasizes the project’s importance and the positive impact it is expected to create.

The feedback received from industry experts and employees has been overwhelmingly positive. Many have expressed their confidence in the training’s effectiveness in improving design and safety practices in Nepal. This validation further emphasizes the project’s importance and the positive impact it is expected to create.

With a project duration of 18 months, Impact Hub Kathmandu is on track to achieve its goal of training at least 200 participants from three different provinces of Nepal. By equipping individuals with the necessary safety skills and knowledge, the project aims to foster a culture of safe engineering practices and innovation throughout the country. The project’s comprehensive curriculum on machine-specific safety practices will continue to be refined and delivered to participants, ensuring they acquire the necessary skills to contribute to a safer and more innovative engineering landscape in Nepal.

Impact Hub Kathmandu and FabLab Nepal remain steadfast in their commitment to empowering young Nepalese individuals with engineering capabilities, entrepreneurship skills, and design expertise. Through projects like “Building Safe Engineering Designs and Practices for Nepal,” they continue to pave the way for a safer and more prosperous future in Nepal’s engineering sector.

Impact Hub Kathmandu and FabLab Nepal remain steadfast in their commitment to empowering young Nepalese individuals with engineering capabilities, entrepreneurship skills, and design expertise. Through projects like “Building Safe Engineering Designs and Practices for Nepal,” they continue to pave the way for a safer and more prosperous future in Nepal’s engineering sector.