Paramendo reached another milestone by conducting a pilot for their tiles made out of recycled PP (Polypropylene) pellets. The site for the pilot was an all-girls school in Bafal, Kathmandu. This pilot not only involved testing and the first installation of the tiles but also facilitated technical knowledge transfer to the team members from Ree.

Initial Preparation

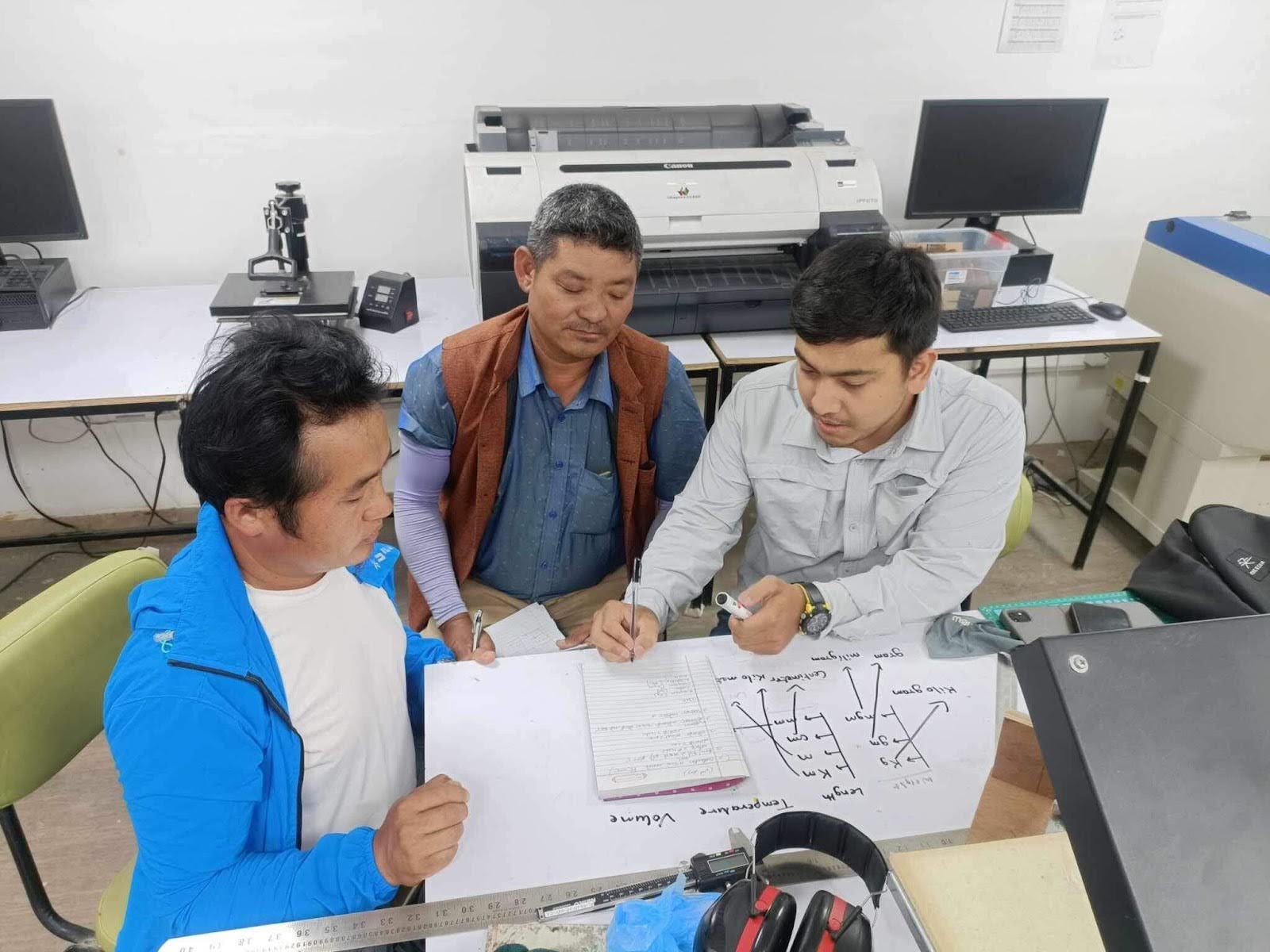

Preparation for this pilot began on June 5, 2024, when team members from Ree (Kaisarki Tamang and Abhishek Tamang) arrived at the premises of Impact Hub Kathmandu (IHK). Here, they received instructions on making the tiles using a heat press. Additionally, the team was made aware of the hazards related to this process and was briefed on all the mandatory safety measures.

Sujit handled the technical aspects of the fabrication process and provided detailed explanations to the team from Ree. Meanwhile, the safety aspects were addressed by Pallab Shrestha (Tech Lead, Impact Hub Kathmandu) and Shashank Dewan (Technical Officer, Impact Hub Kathmandu).

Final Impact

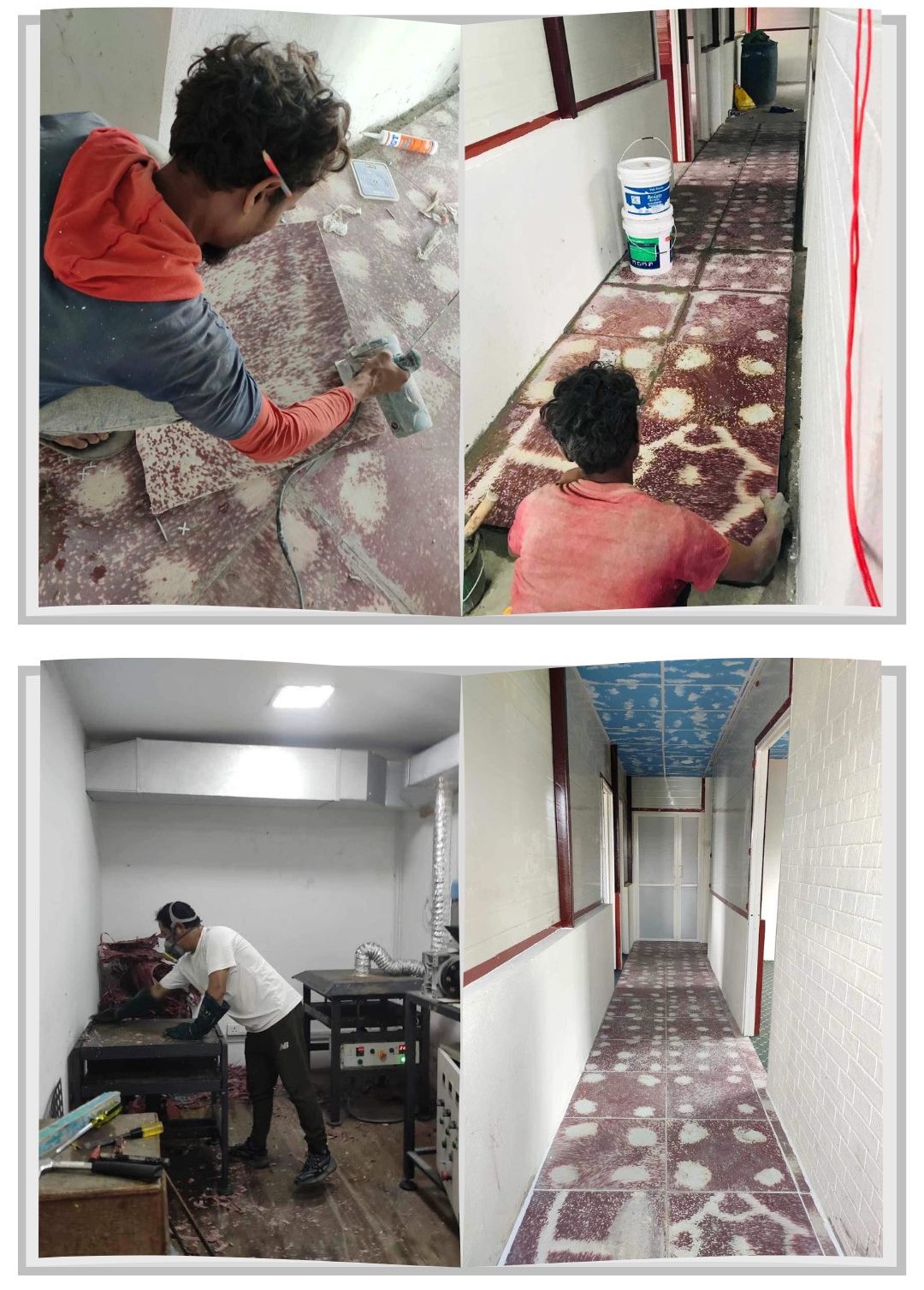

The training and production of tiles continued until June 15, 2024. On June 23, the tiles were transferred to the piloting location, and the installation began the next day, June 24. Additional materials like cement and silicone were used to install the tiles on the floor of a corridor. The work was completed on July 31, 2024. The team successfully recycled 80 kgs of plastic into 36 tiles, which covered a floor area of 102 square feet.

Challenges

The installation process presented several unexpected challenges. Crafting the required tiles proved to be a more time-consuming endeavor than initially anticipated, demanding patience and precision. The uneven surface areas further complicated the task, necessitating additional preparation time to ensure a flawless fit. Moreover, the tight corners and edges required meticulous cutting and careful fitting, adding layers of complexity to an already intricate process.

Lessons Learned

Their experience has highlighted the critical importance of thorough surface preparation as a foundation for a successful installation. By working in small sections with adhesive, they were able to prevent premature drying and achieve better tile adhesion. Additionally, careful planning and accurate measurement proved invaluable, reducing the need for adjustments and re-cuts during the process.

Next Steps

Moving forward, they will closely monitor the installed tiles during the initial usage period, watching for any potential issues. A follow-up inspection will be scheduled to ensure the tiles and grout are performing as expected. Any problems with the products or their real-world performance will be carefully noted for future reference.