Sujit Shrestha, our fabulous and dedicated Intern at FabLab Nepal proudly shares one of the FabLab Nepal impact stories to you this month: exploring and integrating fabrication technology in the health sector of Nepal. FabLab has been supporting Spinal Injury Rehabilitation Center (SIRC) in integrating the 3D printing technology for building assistive devices and also building the capacity of their staff members to continue the use of 3D printing and designing in future and Sugit has been a crucial part of this mission from our hub! He has been proactively leading this initiative and shares with us some of his learnings at FabLab Nepal!

Sujit, FabLab team member (in black) with the SIRC team

The Spinal Injury Rehabilitation Center is a non-profit, charitable organization catering exclusively to the needs of spinal cordnjury victims of Nepal. The Spinal Injury Rehabilitation Center is a non-profit, charitable organization catering exclusively to the needs of spinal cord injury victims of Nepal. Over nearly a decade of work, the Spinal Center has developed a range of facilities to support the spinal injuries of Nepal, who tend to come from the most marginalised bracket of society. However, there is a critical gap: customized and right-fitting assistive devices are not easily available in Nepal. Fablab and SIRC, in collaboration, plan to merge engineering with medicine. The focus was to aid and make better therapy sessions for patients of Occupational Therapy(OT) and Physiotherapy (PT). In countries like Nepal where specific devices are hard to find at first which to buy or import is not possible and secondly, it does not fit with individual patients having specific requirements. In the period of this internship, we had planned to make occupational therapy items and assistive devices using 3D printing. My interest towards product design was a good chance for me to learn and try out new things. With it, I had another task to make a prosthetic for a lovely three-legged cat at Impact Hub. This again is a new and different opportunity for me to learn a new topic, animal-centred design or biomimicry.

Role and role of FabLab at SIRC

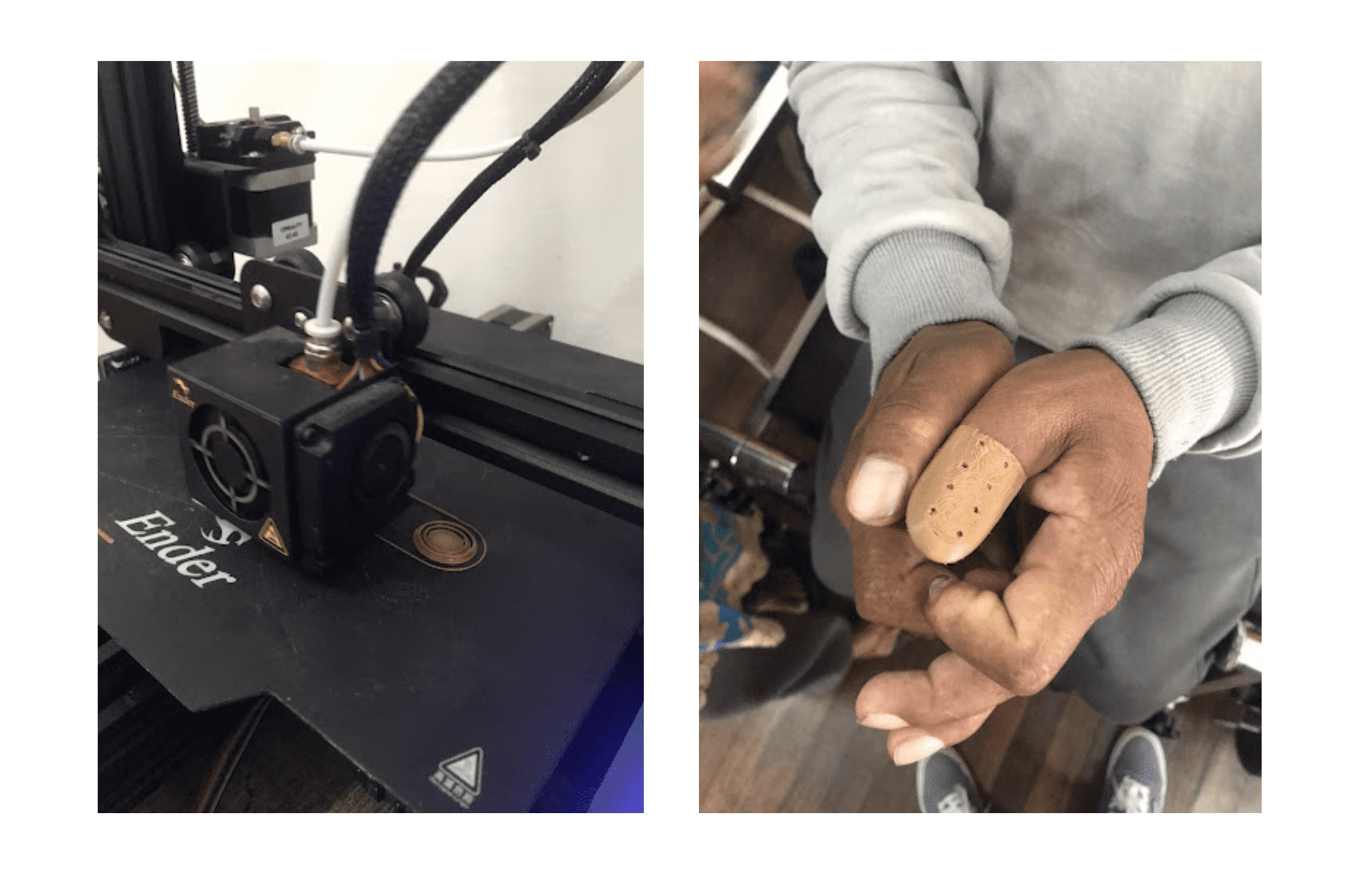

Working in SIRC, we had three major objectives: 1) setting up a 3D printer, 2) designing OT equipment & assistive devices and 3) training the Occupational therapy department and Prosthetic & Orthotics Department (PNO). We completed the 3D printer setup first by troubleshooting the existing printer. Then we conducted the training session for two months covering design modelling, design principles, technologies of 3D printing and slicing & printing the models. Throughout my internship with FabLab in this project, we made thirteen devices, of which five of them were targeted for the specific needs of two of the patients. We must use the Human-Centered Design approach in all of our processes of designing and understanding user needs even in this project. For this, we attended the therapy session with patients to identify the problems and designed the devices with the consultation of occupational therapists.

Some of the projects under this program involved making a prosthetic finger for the patient, an assistive feeding spoon, modification of a DIY therapy device with the help of 3D printing, a thumb brace, an assistive mobile holder, a finger splint and an assistive bottle opener. While consulting and observing the therapy sessions, I was advised to make occupational therapy devices as interactive as possible, such as using games. For this, I made two devices one targeting the shoulder and biceps movement of the patient and the other targeting the finger movement of the patient.

Moving Forward

From the beginning, we’ve been long with the medical director of SIRC, and have been aware of long-term plans for this collaboration, specifically the merger between engineering and medicine. For this purpose, we have had Computer-Aided Design(CAD)and 3D printing training for three persons during my time in SIRC. The training ran for two months for the occupational Therapy in charge, Prosthetic & Orthotic changer and Occupational therapist. So I am quite sure they are capable of modelling, designing and printing simple devices that they need during their therapy session.

My learning during my internship has been out of the box, I have gained a new lens of viewing engineering. My biggest takeaway is the skills we have developed in our curriculum can not only be used to make machines but also for change and aiding others. As a mechanical engineer working with medicine was quite new to me. Engineering has always been fascinating to me, the process of problem-solving designs, the cutting-edge technology for manufacturing have always inspired me to try something new, and here in my internship period at FabLab, I got the chance to try that through this project.