FabLab Nepal in collaboration with JB Consultancy conducted a 11-day workshop on digital fabrication, 3D printing (Fused Deposition Modeling) and CNC (Computer Numerical Controlled) Routing at Impact Hub Kathmandu. The training was a part of the Ministry of Industry’s (MoIss) Industry 4.0 strategy to build hands-on knowledge and skills to the technical workforce on using digital fabrication. Industry 4.0 (I4.0) of Nepal mainly focuses on manufacturing technology and processes that comprise a cyber-physical system (CPS), Internet of things (IoT), Industrial Internet of things (IIOT), Cognitive Computing and Artificial intelligence as innovation towards the computerization and exchange of information. A study conducted in Nepal across 287 industries in 2022, Assessing the industrial readiness for adoption of industry 4.0 in Nepal: A structural equation model analysis states, “The study found that the major problem while adopting I 4.0 is the lack of skilled manpower in the industrial sector.” The purpose this training provided by FabLab in partnership with JB Consultancy was to aid the progress of this era’s industrial revolution. The workshop was divided into two parts, the first five days were dedicated to 3D printing with a gap of a week in-between and the rest of the six days were dedicated to CNC routing.

3D Printing Workshop

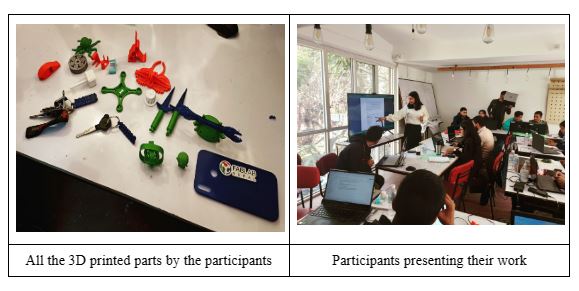

We kicked off the workshop from 30th of January where our FabLab leads: Pallab Shrestha and Shashank Dewan informed the participants about the theoretical aspects of 3D printing, basic information, 2D and 3D design, and slicing software. This allowed participants to get hands-on experience and at the end, all the participants also printed a prototype by themselves. Some used PLA filament, which is a type of hard plastic material, whereas some of them opted for TPU filament which is another rubbery kind of plastic filament. In the end, the participants printed a various prototypes like key rings, stents, quadcopter housing, toys, models, oil sieves, mobile stand, and many more. The participants prepared a document with their findings and learning, presenting those to all other attendees.

CNC Workshop

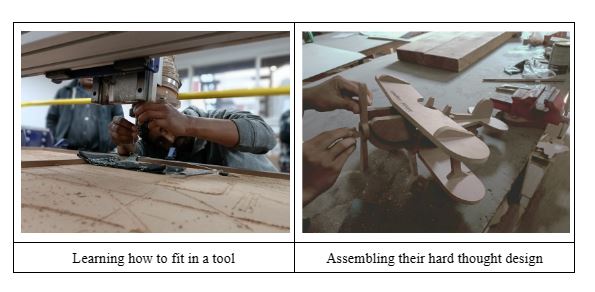

The workshop for CNC began on 12th of February, similar to the previous workshop. Our instructors provided a brief overview of the training, its objectives and the requirements the participants. The first two days were devoted to understanding the theory of CNC machines, 2D and 3D design, and design parameters that we need to be mindful about. We also taught them CAM software required to generate the G-Code which is required for converting ideas into reality. Alongside the technical skills, we dedicated half a day in curriculum specially to provide general orientation and training on safety practices and hazard management while using machinery. We prioritized this session since it’s a very important knowledge and life skill while using any kind of machine. There can be potential hazards and risks while operating and working with the CNC machine without safety consideration. As the fourth day rolled on, the participants started their final design for their individual products. The 5th and final day were devoted to CNC cutting, turning the virtual designs of the participants into reality along with a presentation of the findings and learnings by each participant. We also had space for participants to give feedback and input at each the workshop. The workshop officially concluded with distribution of certificates to all the participants.

We’re delighted to be able to contribute to the technological needs and Industry 4.o strategy of Nepal and support the partners through our small efforts to through this training program. It is our biggest accomplishment being a community resource center, that we’ve been able to provide the technological resources for diverse people. Stay tuned as FabLab will be organizing a workshop on safety practices for digital fabrication in the near future!